To design rope drives in lifts, it is in many

cases still indispensable to this day to

conduct experimental investigations into

sample ropes, for example to determine

elongation behaviour in the longitudinal

rope direction. Since its establishment,

the Institute of Mechanical Handling and

Logistics (IFT) of the University of

Stuttgart has been engaged in research in

the field of rope technology.

I

n many modern lifts, ropes as lifting gear are

a decisive factor for the service life and main-

tenance intensity of the entire system. The

rope not only has to be wear-resistant, but also

reliably indicate its wear condition and above all

the replacement state of wear. The replacement

state of wear of the rope – i.e. permanent da-

mage – has been reached when the system still

operates safely, but an unsafe condition could

be reached in the near future.

Spontaneous damage to the rope can for ex-

ample also occur due to external mechanical

factors – this frequently occurs in the area of

crane construction. By contrast, ropes in lifts

usually wear out on account of over-rolling of

the discs. What is important in this regard is clear

and reliable indication of the so-called replace-

ment state of wear, the time of rope replacement.

Furthermore, an excessively high modulus of

elasticity (e-modulus) can stretch the rope under

the load of the car too much and as a result trig-

ger a very uncomfortable sinking of the car upon

entry and regulation problems in the travel drive.

A change in the modulus of elasticity and as a re-

sult in the rope elongation behaviour during the

rope’s service lift can be even more problematic.

Apart from the service life of the lifting gear, the

modulus of elasticity is an important parameter

for lift ropes and should be determined according

to application.

The IFT (see box) regularly conducts expe-

riments on the institute’s own traction testing

machinery to measure the modulus of elasti-

city. There is no linear progression in the rope

stress-rope strain curve for the rope’s strength.

Consequently, it is very important during the

measurement to take into account the use of the

rope and the associated rope forces that occur.

For example, for the rope tensile forces, safety

factors between 14 and 25 for the lifting gear are

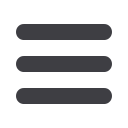

normally used. At the IFT, three measuring rigs

are available for strain measurement of the rope

for various force ranges, installed in two tensile

testing machines (for example, in Fig. 1). Measure-

ments can either be conducted by a parallel rod

clamped on the rope at two measuring points

or by two rope displacement pickups evaluated

in parallel (shown in Fig. 1). The result of the

measurement is a stress-strain diagram (Fig. 2).

Normally, the secant modulus of elasticity

according to Feyrer [1] is determined in the ex-

periment (yellow in Fig. 2). For this purpose, the

rope is extended between the minimum and ma-

ximum rope loads occurring in the operation of

the rope, that is to say, run to the upper and lower

limit load several times in succession. After this,

the tenth extension cycle for example is evalua-

ted – the rope extension is determined from the

measurement log while running past the two

observation limits.

In addition to the secant modulus, the tangent

modulus (shown red in Fig. 2) can also be deter-

mined from the intersections of the elongation

curves with the observation limits. In each case,

the difference between loading and load reduc-

tion is important, since as a result of inner fricti-

on in the rope, the elasticity behaviour can in part

differ markedly depending on the direction.

⇤

STEFAN HECHT

The author is a qualified engineer and head of the

research group Destructive Rope Testing of the Insti-

tute of Materials Handling and Logistics (IFT) of the

University of Stuttgart.

[1] Feyrer, K., Wehking, K.-H.: Drahtseile – Bemessung,

Betrieb, Sicherheit, Springer Verlag, Berlin, 2018

Abb. 1: Messaufbau zur Bestimmung des Seil-Elastizitätsmoduls

Fig. 1: Measuring rig to determine the rope modulus of elasticity

WHAT IS THE IFT?

Since its establishment in 1927, the Institute of

Mechanical Handling and Logistics (IFT) of the Uni-

versity of Stuttgart has been engaged in research

in the field of rope technology. The rope technology

department concentrates on wire ropes, fibre ropes,

personal protective equipment, cableway techno-

logy and rope use. It provides studies to determine

rope service life in continuous bending fatigue

and extension experiments, static and dynamic

experiments, drawing up damage expert opinions,

safety and risk analyses, cableway technology and

destructive and non-destructive rope testing. Fur-

thermore, the IFT advises industrial companies as

well as the operators of installations and buildings

on the specific use of ropes. The department is re-

cognised worldwide as a testing and expert opinion

authority. The over 1300 m² experiment hall at the

IFT, the rope laboratory, is equipped with testing

machinery and installations for rope testing, in part

developed at the laboratory itself.

WAS IST DAS IFT?

Das Institut für Fördertechnik und Logistik (IFT) der

Universität Stuttgart befasst sich seit der Grün-

dung im Jahr 1927 mit der Forschung im Bereich der

Seiltechnologie. Die Schwerpunkte der Abteilung

Seiltechnologie sind die Bereiche Drahtseil, Faser-

seil, Persönliche Schutzausrüstung, Seilbahntech-

nik und Seilanwendung. Es bietet Untersuchungen

zur Ermittlung der Seillebensdauer in Dauerbiege-

und Schwellversuchen, statische und dynamische

Prüfungen, die Erstellung von Schadensgutachten,

Sicherheits- und Risikoanalysen, die Seilbahn-

technik sowie zerstörende und zerstörungsfreie

Seilprüfungen. Außerdem berät das IFT Industrie

unternehmen sowie Betreiber von Anlagen und

Bauwerken bei der spezifischen Anwendung von

Seilen. Die Abteilung ist weltweit als Prüf- und

Gutachterinstanz anerkannt. Für Seilprüfungen ist

die über 1300 m² große Versuchshalle am IFT, das

Seillabor, mit zum großen Teil eigenentwickelten

Prüfmaschinen und -einrichtungen ausgestattet.

Foto: © IFT