Lift

journal 3/2018

11

Aufzugsystem für Überlastschutz und mehr

Elevator system for overload protection and more

Die Engineering-Teams des Unternehmens

Zemic haben nach eigenen Angaben die

effizienteste und kosteneffektivste Lösung

zur Überlast-Erkennung für Aufzüge und

Hebesysteme entwickelt.

Zur Entwicklung einer neuen und inno-

vativen Lösung für den Überlastschutz

von Aufzügen arbeiteten die Engineering-

Teams von Zemic mit den wichtigstenAuf-

zugherstellern zusammen. Für Aufzugher-

steller ist das Thema Überlast von großer

Bedeutung. Noch besser wäre es jedoch,

The engineering teams at Zemic have

worked together to make the most ef-

ficient and cost effective solution for

overload detection systems for elevators

and lifting systems.

The engineering teams at Zemic worked

together with key elevator manufacturers to

develop a new and innovative solution for eleva-

tor overload protection. The elevator manufac-

turers indicated that overload is a main feature,

however it would be more optimized when this

could be combined with topics such as energy

savingmotor management and child protection.

Besides functional requirements the engineering

teams were challenged by specific product de-

mands such as shape of the loadcell, installation

requirements and specific market requirements.

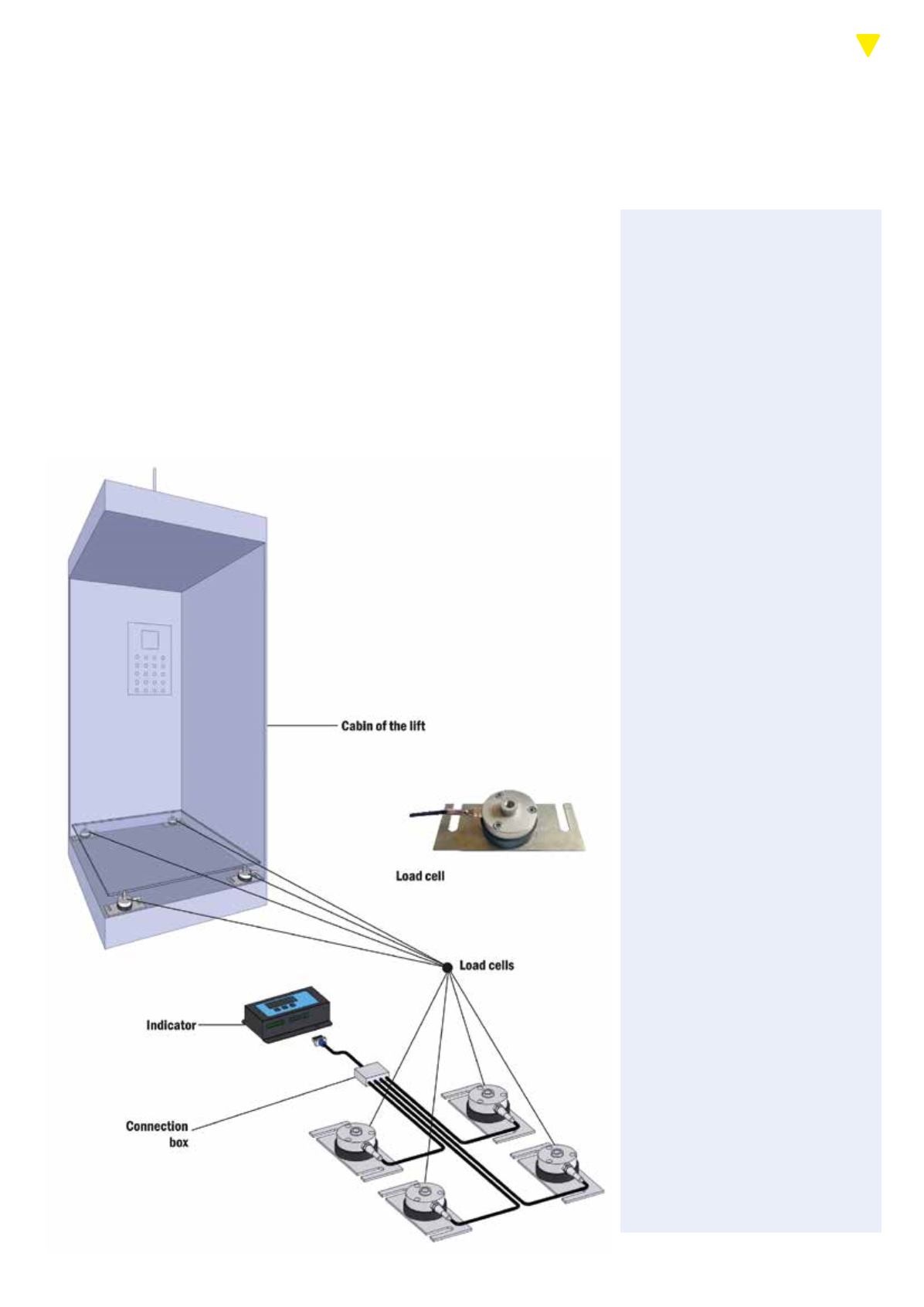

Zemic introduces three weighing kits based on

three different ways lift / elevator companies are

measuring the weight. We offer complete solu-

tions tomeasure theweight under the cabin, un-

der the cable springs and into the cable springs.

Zemic and the Elevator Market:

• Elevator weighing system

• Selected most efficient solution

• Elevator motor management for energy saving

• Zemic Europe, force partner of the Elevator

Industry

The Zemic ElevatorWeighing systems havemany

features. Zemic will mention the unique selling

points of the system to show why and how this

particular lifting system is used throughout the

world. Energy saving is one of the extra require-

ments which was highlighted. This is the reason

the engineers built in the power regulation op-

tion for the elevator engine. The power needed

to drive the engine depends on the amount of

loading weight in the elevator.

In the elevator industry overload indication is one

of the key features in each lifting device. Force

sensors are highly sensitive and can be perma-

nently damagedby overload and shock overload.

This is why the maximum overload % is always

given on the force sensor product datasheet.

When developing this sensor we integrated a

rubber shock absorber. This elastomer protects

the loadcell from dynamic overload forces and

secondly provides an equally shared load over

the sensors.

Some unique features of the elevator force sen-

sors is the round shape for an optimized force

introduction and thematerial used. The working

of the loadcells do not depend on the angle of

the force introduction. The round shape allows

you to compensate non-axial force effects. The

loadcells are suited with a cable spring fitting

on the cable exit which protects the wires from

bending and breaking, which increases the

Produkte und fachberichte /

Products and technical reports

Fotos:

© Zemic Europe

wenn der Überlastschutz mit weiteren

Merkmalen wie zum Beispiel Energiespar-

Motormanagement und Kindersicherung

kombiniert werden könnte.

Neben den funktionalen Anforderungen

bestand für die Engineering-Teams die

Herausforderung in spezifischen Produkt

anforderungen wie Form der Wägezelle,

Einbauanforderungen und spezielle Mark-

terfordernisse.

Zemic stellt drei Wägekits vor, mit denen

Hersteller von Aufzügen das Gewicht auf

drei verschiedene Arten erfassen können.

Das Unternehmen bietet Komplettlösun-

gen zur Messung des Gewichts unter dem

Kabinenboden, unter den Zugseilfedern

und in der Zugseilbefestigung der Kabine.

Zemic und der Aufzugmarkt:

• Aufzug-Wägesystem

• effizienteste Lösung

• Aufzug-Motormanagement zur Ener-

gieeinsparung

• Zemic Europe, Partner für Kraftmessung

in der Aufzugindustrie